The Whole Process under our control

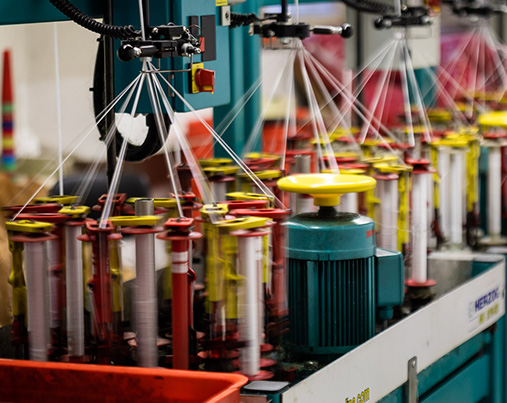

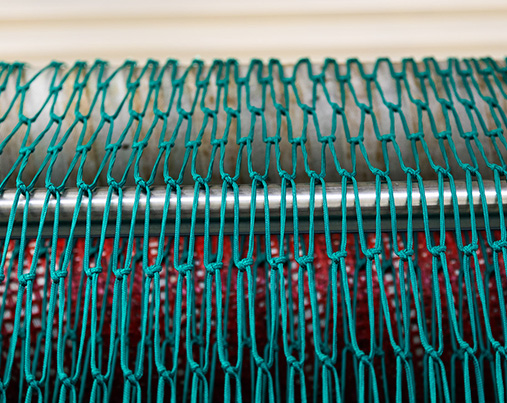

We begin with fiber, selected from certified exporters. From knitted string we then make nets and give special care to the quality of our knots. At the end of production, the nets are inspected and cut by hand. Since we have the whole production process under our control, we can guarantee a high quality of our netting.